History

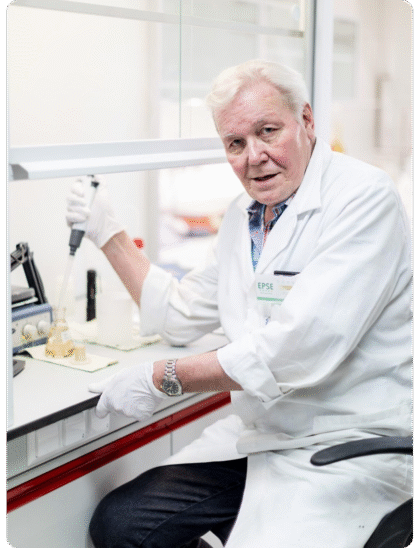

EPSEs roots date back to the early 2000s, when the inventor of the EPSE™ Method, Vesa Rissanen, owned a pickling plant where airplane parts were hard chrome plated. In the process, numerous metals dissolve in the acid, eventually forming hazardous waste. In order to overcome the waste handling expenses, Rissanen did several experiments and eventually managed to precipitate the acid so that the end result was pure water and multimetal precipitate. However, the airplane factory was closed and his company closed. The precipitation formulas remained in the desk drawer for years.

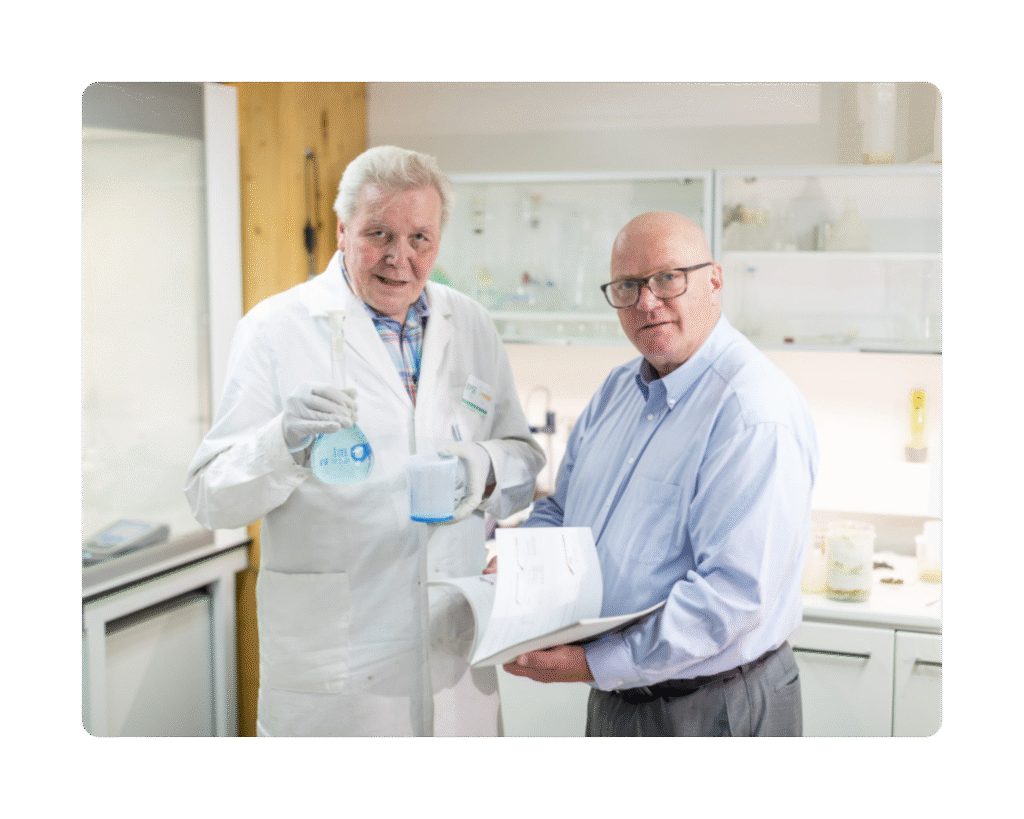

A decade later the information about the precipitation formulas was brought to the attention of two entrepreneurs and a planning and execution of the Method’s commercialization begun. At first, the operation was small-scale and focused only to the wastewaters from pickling industry. Around the same time mining waste water problems got a lot of negative publicity in Finland, and the group started to investigate if the method could be used in separating metals from mining waste waters. For this purpose, in 2012 Global EcoProcess Services Ltd. – EPSE was established.

Towards success

A wide range of experimentation, trial, error and learning fits into EPSE’s story. We have found many valuable partners with whom we’ve been able to test our method in various fields and thus find our core competencies. EPSE currently holds four patents for its technology, the EPSE™ Method, one of which is the first main patent and the others are supporting patents.

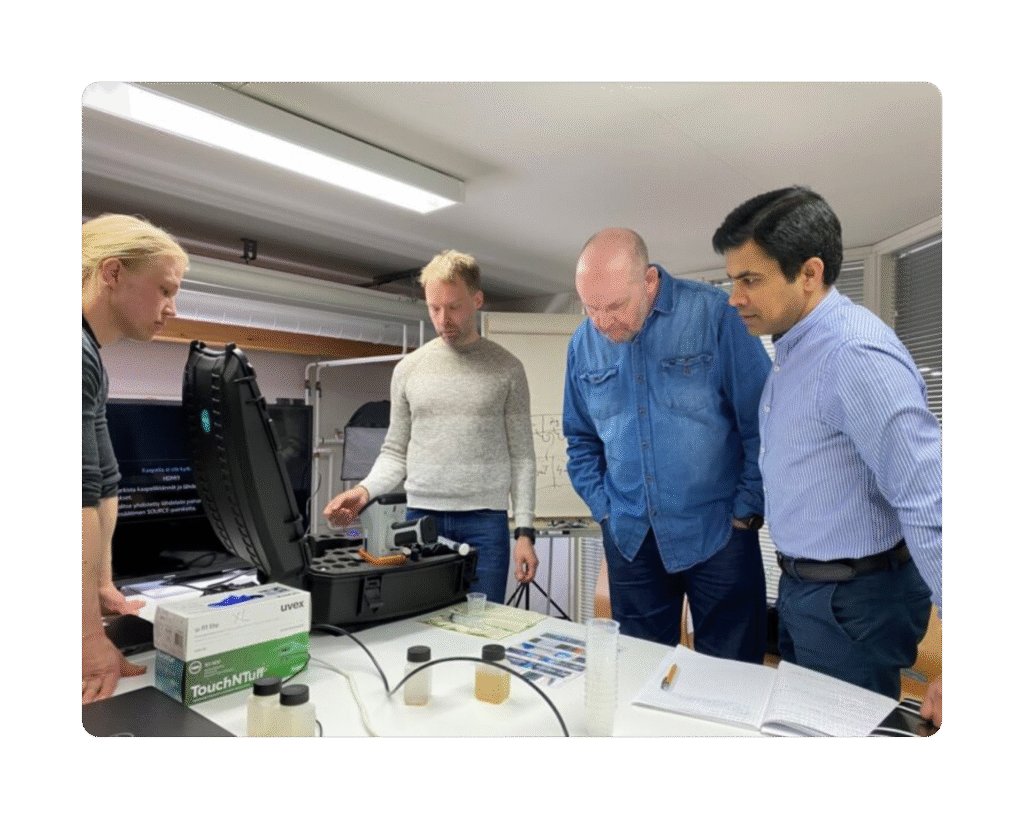

In the spring of 2019, EPSE received 1,9 M€ project funding from European Commission Horizon 2020 innovation programme. With this funding, the first portable Mobile EPSE™ Proto pilot equipment was planned, built and tested. It has been widely used in various customer locations across Finland. In 2020 the same funding was used to build the next, improved Mobile EPSE™ and in the same year EPSE changed its’ name to EPSE Oy (Ltd.).

Today

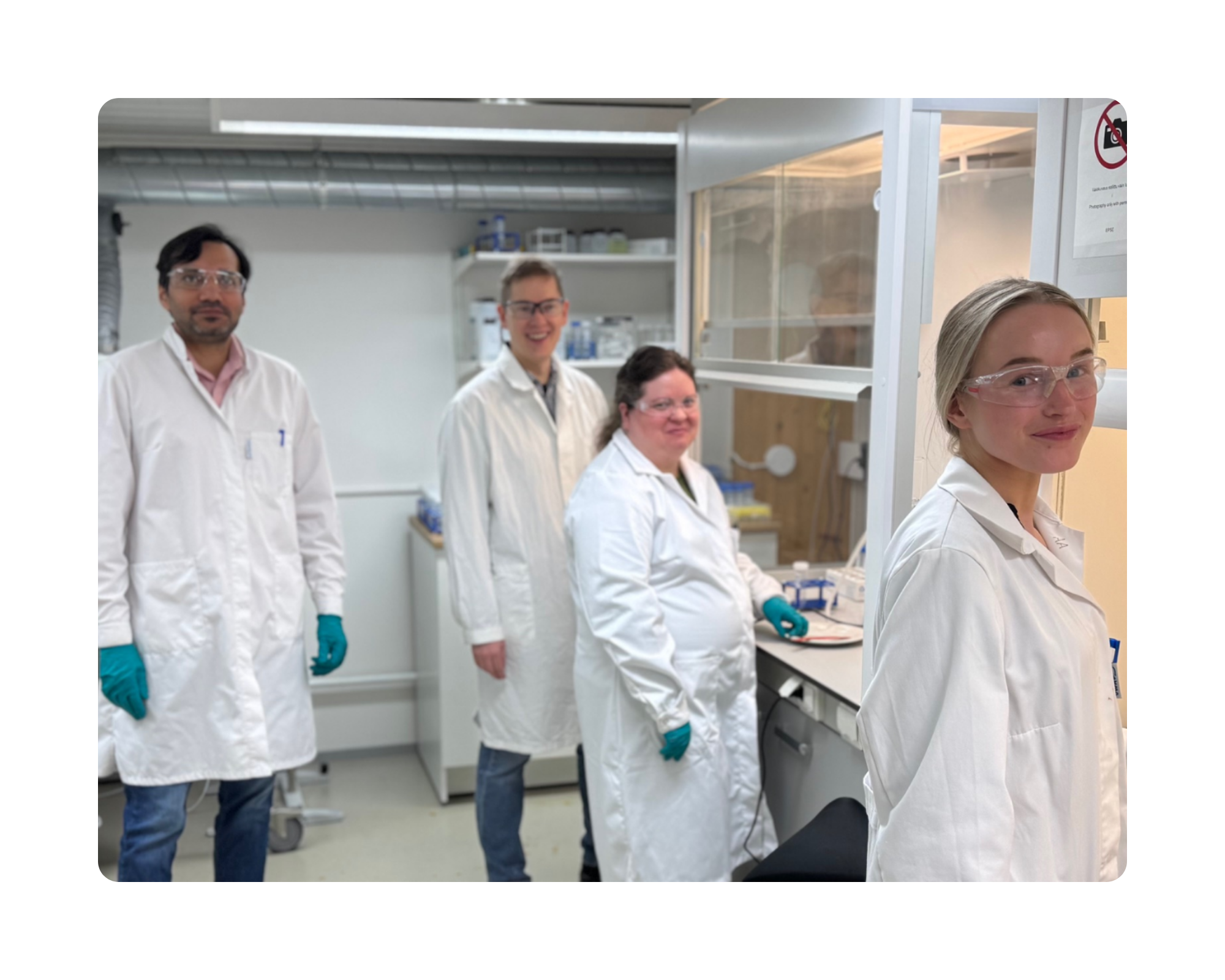

Currently EPSE is growing fast as a reliable operator in the field of water treatment and new projects within Europe and the rest of the world arise constantly. EPSE Team has gradually grown from a few people into a close group of specialists and the need for growth has been constant. In addition, EPSE has found valuable local partners in its target markets, which have enabled the implementation of international projects. EPSE has two portable piloting equipment that have been in use both in Finland and all over the world. Also a large-scale concentrated water treatment plant specialized in treatment of water containing heavy metals is under planning.

EPSE is on its’ way towards being the market leader in treating wastewater containing soluble metals, simultaneously promoting circular economy and protecting the environment.

Stay up to date with our latest projects by following us on social media!