The On-site Piloting verifies the functionality of the EPSE™ Method in the customer’s circumstances. It also supports the calculation of investment and operating costs: during piloting, EPSE Pilot Operators collect accurate data on process parameters and collect water and precipitate samples to ensure the reliability of the results. If the customer so requests, samples can be delivered to an approved external laboratory for analysis while duplicate samples are delivered to EPSE’s own laboratory for quality assurance purposes. This ensures that the treatment method meets the set quality requirements and specifications.

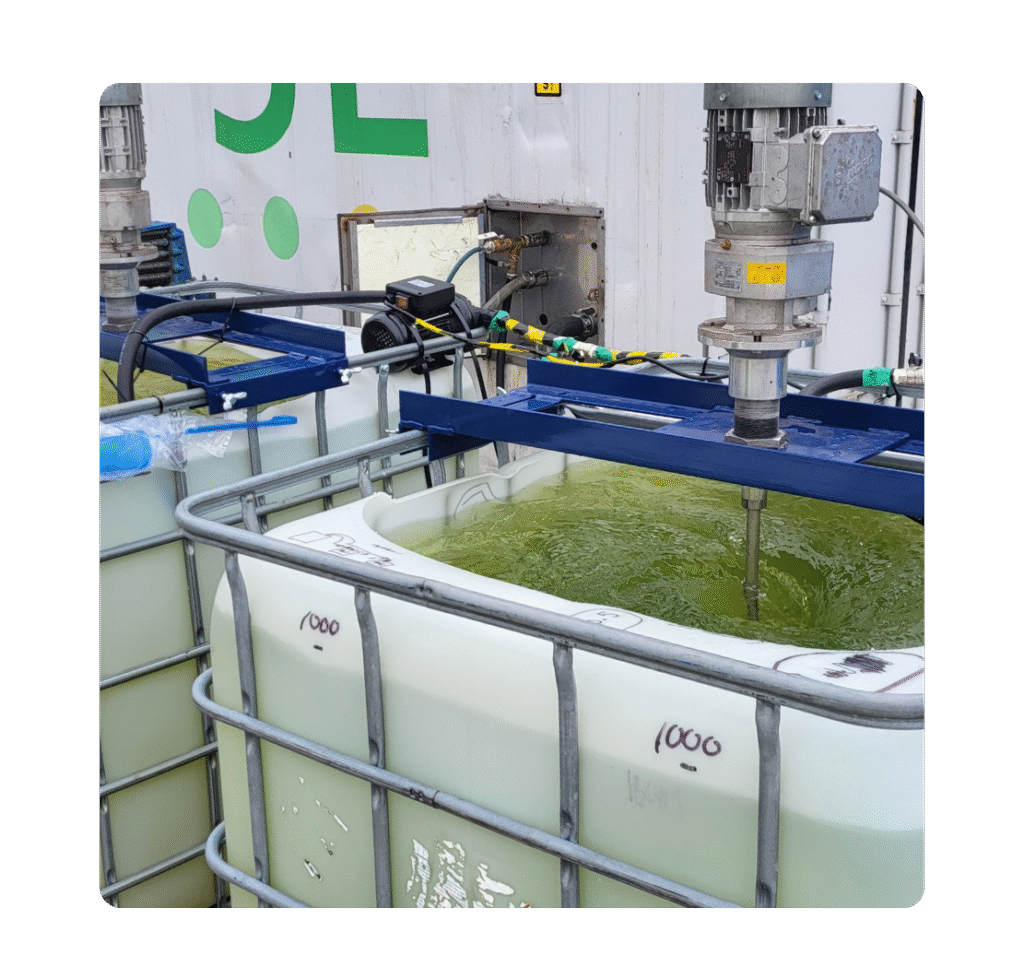

EPSE’s technology can be piloted using the portable Mobile EPSE™ or some other client-tailored solutions, such as utilizing existing equipment or IBC containers. The latest addition to EPSE’s piloting solutions is the SCOPE laboratory-scale pilot equipment, which offers advantages such as easy transport and commissioning.

Read more about

Industrial water treatment piloting with Mobile EPSE™

The Mobile EPSE™ is a fully automated piloting unit for side stream piloting and it can be used for both continuous (24h) or batch run according to the customer’s wishes. In the process water flows through the system and the treated, metal free water comes out of the system in the other end – as well as the multi-metal precipitate.

- Ability to run either a continuous / batch process

- Logic control that allows customization of the EPSE recipe on site

- Remote run via mobile device

- All piloting data can be collected for further use

- Designed for harsh conditions and chemical durability

- Capacity of 1 m3/h, can be adjusted if needed (0,2 – 2,0 m3/h)

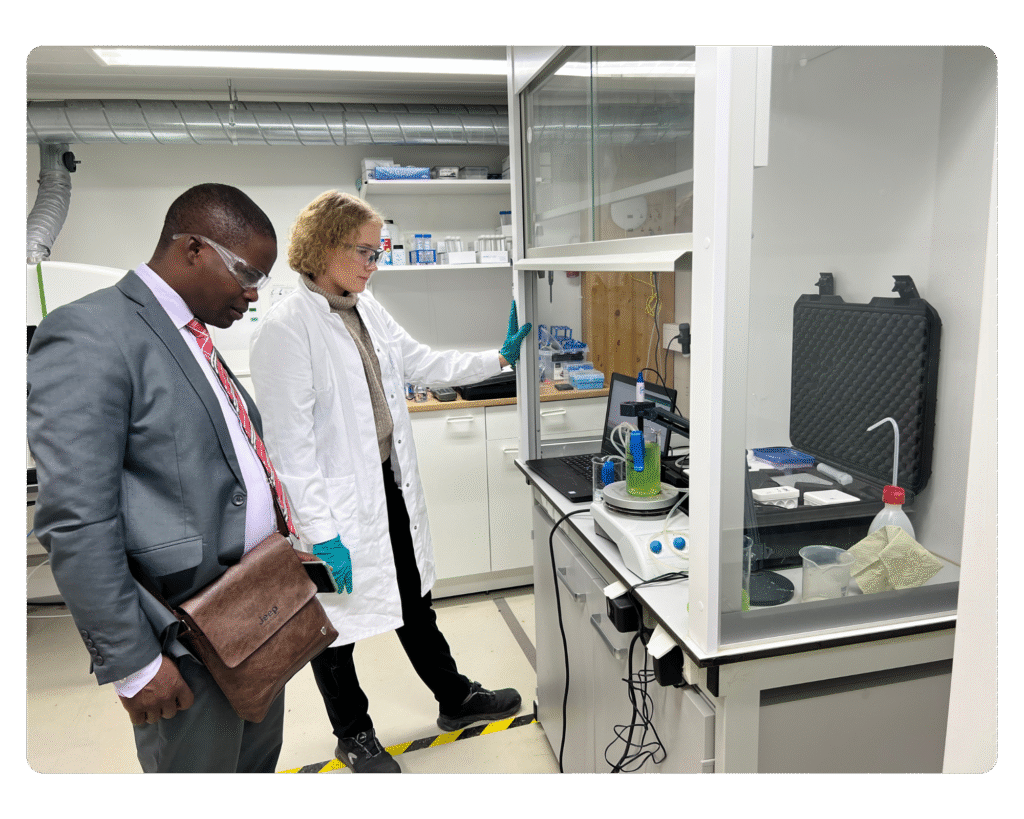

SCOPE Laboratory-scale piloting

SCOPE (Scalable Continuous Piloting Equipment) – the laboratory-scale pilot plant is designed to simulate EPSE’s industrial-scale pilot equipment and to demonstrate the functionality of the EPSE™ Method without having to move heavy equipment to the customer’s premises. The industrial pilot projects involve the treatment of up to hundreds of cubic meters of wastewater, whereas SCOPE’s operating volumes are measured in liters. The equipment can be transported with ease to even remote locations, as it can be carried as checked luggage and the set-up requires only basic laboratory equipment.

SCOPE can be used to simulate EPSE process in the following ways:

- Batch

- Continuous

- Divided flow

- Customized solutions for additional process measurements and analyses agreed upon with the customer

Customized pilot solution

Especially in situations where the customer’s own equipment and facilities are suitable for EPSE processing without major modifications, we strive to conduct the pilot with existing equipment. We can also utilize other types of containers, such as IBC containers with integrated mixers, portable pumps, and other easily transportable and transferable solutions.

Like in all pilot projects, cooperation with the client’s technical and operational representatives plays a key part in planning and execution of a successful trial. Our Technical Team can design a pilot solution for any conditions!